All Services

Your Total Electronics Solution

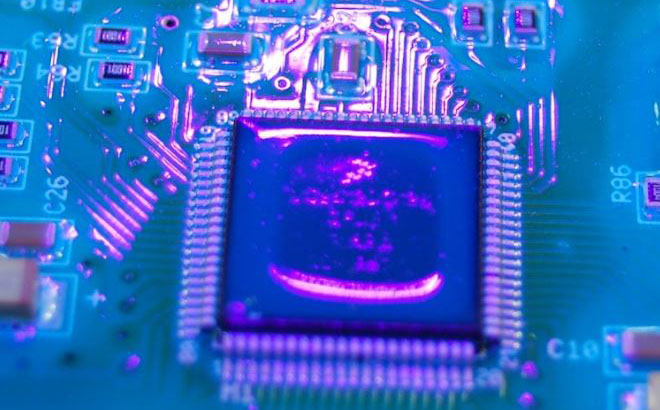

SoPark’s Electronic Manufacturing Services

SoPark offers full turnkey and consignment-based orders for all your electronic needs. We are committed to high quality standards and excellent customer service.

Our Program Management Teams will meet individual needs of each customer and deliver the best product available in a timely and friendly manner.

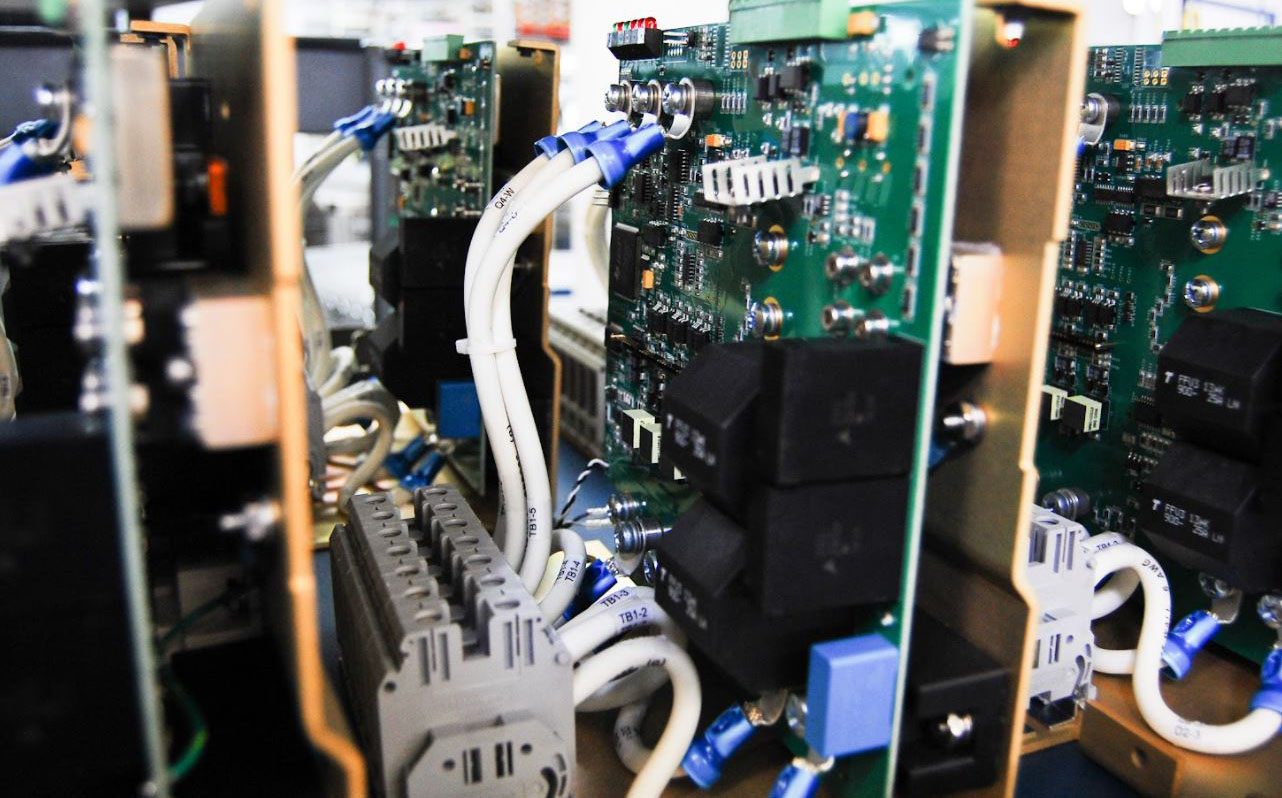

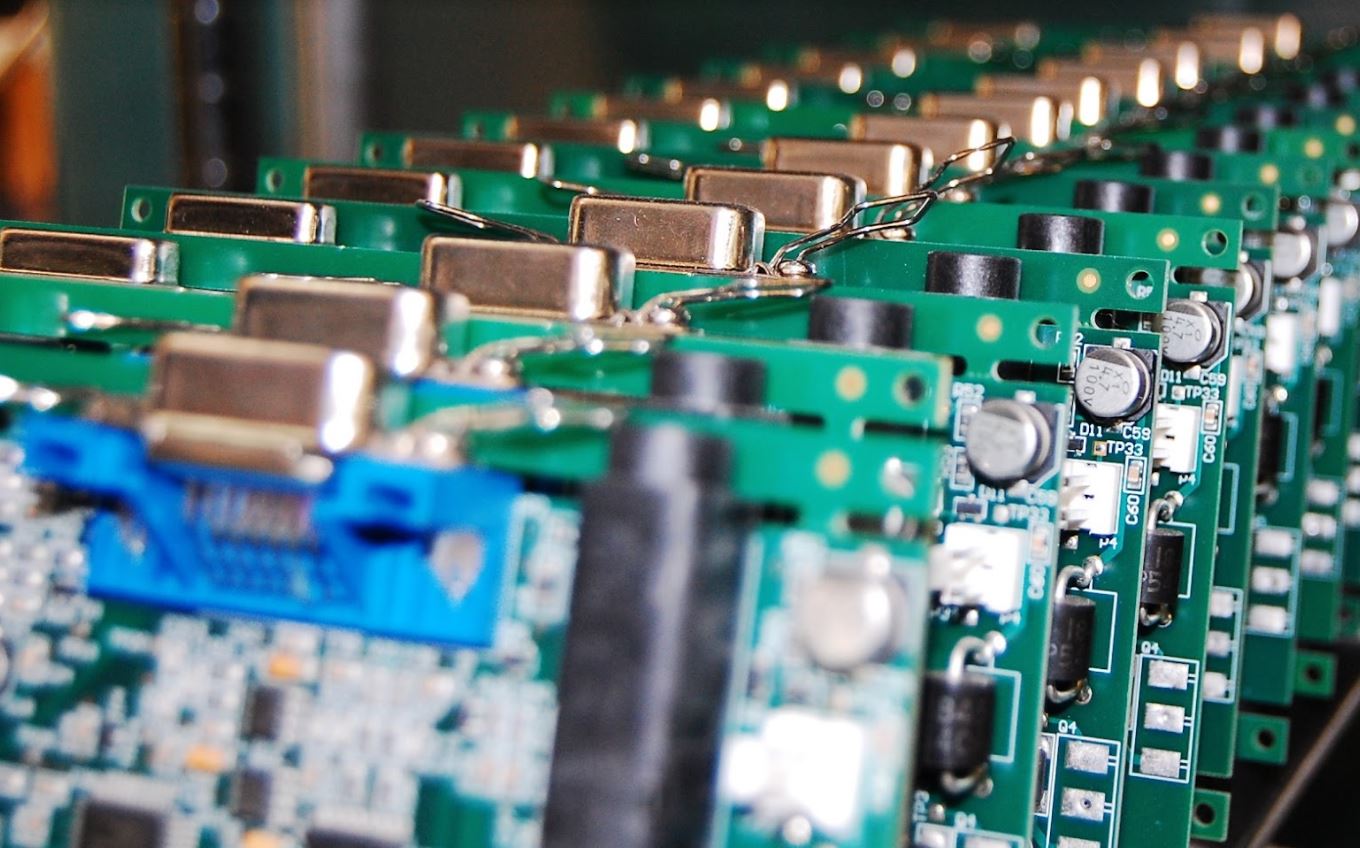

Board Assembly Tech Specs

- SMT packages placed: from from 0402 to 2in x 2in size packages and 12 mil minimum pitch devices

- SMT placements/month: 28 million

- Thru-hole placements/month: 2 million

- Maximum board width and length: 16in x 24in

- Typical run size: 25-10,000/month

- Workmanship: J-STD-001, IPC-A-610

- Materials procurement: Full in-house procurement capabilities, turn-key, consignment, mixed